Home » Blog » Applications » Variable speed drive for ID Fans in mining industry

Variable speed drive for ID Fans in mining industry

In most middle/large mining companies, power consumption of motor accounts for 50% of total power consumption. LV variable speed drive is very common. But, defectiveness of MV variable frequency technology, and voltage withstand capacity of components have been restricting MV variable speed drive development and its application. In recent years, with rapid development of MV technology and voltage withstand function, MV variable speed drive has been used widely. Its energy saving effect is considerable.

Project introduction

There were 4 low voltage motors (315kW, 562A, 1476r/min) in flue gas purification system. In general, 2~3 motors worked and another was spare. Fans connected in parallel. Sub-pressure was controlled by valve. Valve opening was controlled just by personnel experience. In 2005, plant decided to reform purification system with medium voltage variable speed drive. Mode of one work and one spare was suggested to ensure safety and reliability.

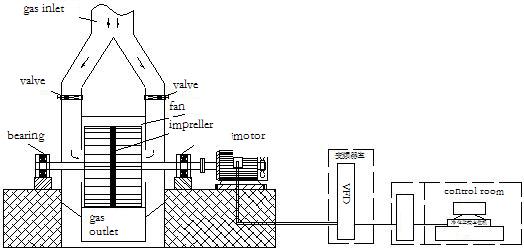

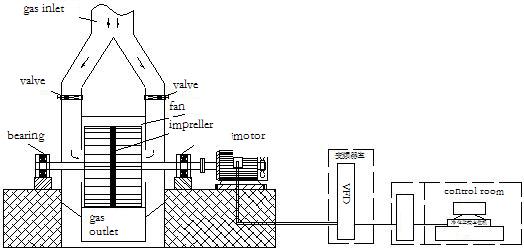

Purification system layout

1. Driving equipments

MV asynchronous motor: YP7560-6, 1000kW, 50Hz , Ve=6300V,Ie=108.95A; ne=994r/min; cosφ=0.876, insulation class: F, connecting: Y, allowed to start once in hot state and twice in cold state.

2. Centrifugal ID fan

Model: Y7-2X36-22F; 338600m3/h; 7500Pa; ne=990r/min; 1000kW.

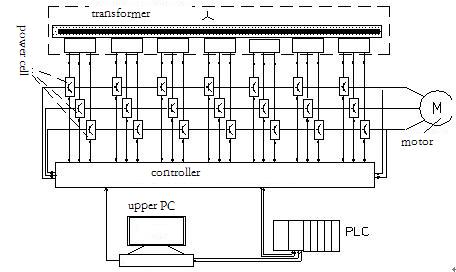

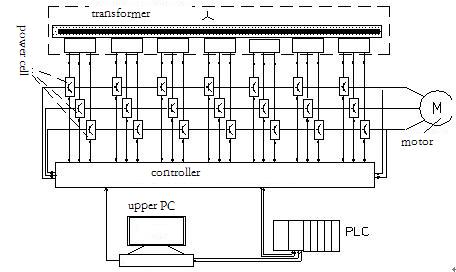

Gozuk variable speed drive adopts technology of cell-cascaded, high-medium voltage source, 6kV input. Medium voltage is transferred to low voltage through transformer. Then it goes through diode and IGBT inverter. Then cells cascaded output 6.3kV.

The variable speed drive has been running stably in flue gas purification system for 3 years since August, 2005. System also runs healthily. Energy saving is considerable and achieves expected goal. It also meets technology requirement and improves purification effect, which makes plant be prized by local environmental protection bureau. According to related statistics, power consumption of purification system has been down 19%. Actual data is in following:

Conclusion

Variable speed drive application in purification system optimizes the system performance, improves purification effect, reduces power consumption greatly. According to related statistic, flue gas consumption reduces 19m3/t. Total power consumption reduces 137000kW.h per month.

Project introduction

There were 4 low voltage motors (315kW, 562A, 1476r/min) in flue gas purification system. In general, 2~3 motors worked and another was spare. Fans connected in parallel. Sub-pressure was controlled by valve. Valve opening was controlled just by personnel experience. In 2005, plant decided to reform purification system with medium voltage variable speed drive. Mode of one work and one spare was suggested to ensure safety and reliability.

Purification system layout

1. Driving equipments

MV asynchronous motor: YP7560-6, 1000kW, 50Hz , Ve=6300V,Ie=108.95A; ne=994r/min; cosφ=0.876, insulation class: F, connecting: Y, allowed to start once in hot state and twice in cold state.

2. Centrifugal ID fan

Model: Y7-2X36-22F; 338600m3/h; 7500Pa; ne=990r/min; 1000kW.

Variable speed drive structure and principal

Gozuk variable speed drive adopts technology of cell-cascaded, high-medium voltage source, 6kV input. Medium voltage is transferred to low voltage through transformer. Then it goes through diode and IGBT inverter. Then cells cascaded output 6.3kV.

Benefits of variable speed drive reform

The variable speed drive has been running stably in flue gas purification system for 3 years since August, 2005. System also runs healthily. Energy saving is considerable and achieves expected goal. It also meets technology requirement and improves purification effect, which makes plant be prized by local environmental protection bureau. According to related statistics, power consumption of purification system has been down 19%. Actual data is in following:

| NO | Furnace | Subpressure (Pa) | Frequency (Hz) | Current (A) | Result |

| 1 | 1system | 960—1020 | 19 | 26 | Up to standard |

| 2 | 2 systems | 1000—1100 | 24 | 34 | Up to standard |

| 3 | 3 systems | 1050—1150 | 27 | 41 | Up to standard |

| 4 | 4 systems | 1100—1200 | 31 | 47 | Up to standard |

| 5 | 5 systems | 1160—1250 | 35 | 52 | Up to standard |

| 6 | 6 systems | 1200—1130 | 38 | 58 | Up to standard |

Conclusion

Variable speed drive application in purification system optimizes the system performance, improves purification effect, reduces power consumption greatly. According to related statistic, flue gas consumption reduces 19m3/t. Total power consumption reduces 137000kW.h per month.

You may also like:

High performance variable frequency drive makes a measurement of the torque through the current to control the brake, for other it's based on speed reference. Then it depend the brake to stand still the motor ...

Dithering the switching frequency of a SMPS (SSFD) introduces sideband energy that by the conservation of energy must result in a reduction in harmonic-peaks. There are two important characteristics of a ...

In fan application, should we run the variable frequency in vector control mode or v/f mode? what are the pros and cons of both the modes. what are the methods to find out the correct running of the motor?

It ...

say there is a permanent fault on overhead transmission line, the distance / line differential protection should operate and trip respect circuit breaker (CB) which is feeding the fault. This protection relay ...

Variable frequency technology is a new drive technology which adopts advanced electronic technique, computer control technique and communication technique. It goes ahead of any other speed adjusting methods. ...

VSD blog: A deep observation of automation control industry, especially in AC motor variable speed drive for industrial motor controls.

VSD blog: A deep observation of automation control industry, especially in AC motor variable speed drive for industrial motor controls. Hot Tags

Featured

7 months back I was involved in a harmonics evaluation study at Budweiser. This was one of many I've participated in over the past 20 years, basically because in facilities like ...

Most of variable speed drives are applying on high temperature fans, kiln head coal mill fans, kiln head surplus fans, raw mill circulating fans and so on. Two production lines ...

Variable speed drive application in purification system optimizes the system performance, improves purification effect, reduces power consumption greatly. According to related ...

The motor power factor does not make a big difference other than giving an idea of loading. In regards to the variable speed drive fixing power factor everyone is mostly correct. ...

A soft starter is a basic device which will ramp up the speed of your motor to full speed over a preset time, easing mechanical stress and also easing the high inrush currents ...

What's New

Variable Speed Drive Harmonics

Variable speed drive energy saving in cement industry

PLC and DAQ

Is it good to do preventive maintenance for variable speed drives

Does motor starts number affect motor life?

Variable speed drive for ID Fans in mining industry

Regenerative power frequency back to line power

Variable speed drive for axial-flow fans

Variable speed drive energy saving in cement industry

PLC and DAQ

Is it good to do preventive maintenance for variable speed drives

Does motor starts number affect motor life?

Variable speed drive for ID Fans in mining industry

Regenerative power frequency back to line power

Variable speed drive for axial-flow fans